Current Projects

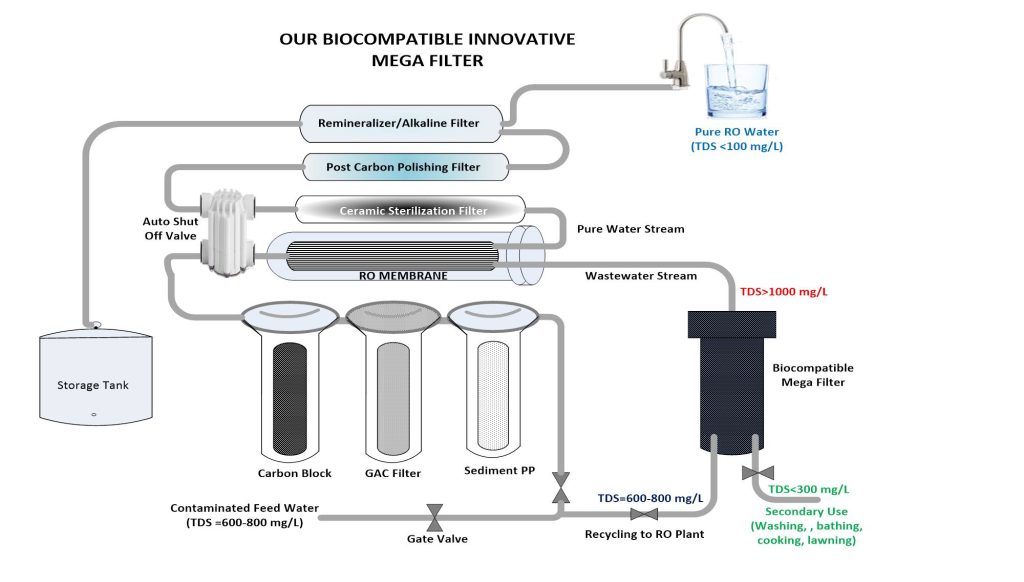

1. Biocompatible Mega Filter for RO Wastewater Reuse

Project Overview:

In recent years, the environmental implications of wastewater generated by Reverse Osmosis (RO) filtration systems have garnered significant attention. Traditional RO systems often operate at a ratio of 2:1, meaning that for every gallon of purified water produced, an equal or greater volume of wastewater is generated. This waste stream poses challenges to water conservation efforts and has detrimental effects on the environment, particularly in areas facing water scarcity. To address these pressing issues, our project aims to develop an innovative solution: a biocompatible mega filter specifically designed to treat and reuse the wastewater generated by RO filtration plants. This mega filter will serve as a secondary filtration system, efficiently capturing and adsorbing various pollutants found in the waste stream, thereby minimizing the environmental impact and enhancing water sustainability.